Reliable Handmade Kitchen Sink Manufacturer

Dexing Kitchen & Bathroom Co., Ltd., which was established in 2009, is a leading manufacturer of stainless steel sinks and kitchen faucets, we specialize in innovative designs like apron-front workstations and single-bowl solutions. Our 16-gauge sinks combine functionality with bold aesthetics, perfect for luxury kitchens and transitional spaces.

Trusted by architects and wholesalers, we deliver corrosion-resistant, easy-to-clean sinks and faucets. From undermount installations to granite composite countertops, our products blend craftsmanship with small-radius corners for a seamless kitchen experience.

Types of Products We Made

Handmade Kitchen Sink

Handmade stainless steel sinks offer endless customization possibilities. Crafted with precision, these unique pieces can be tailored to your exact specifications, ensuring a perfect fit for your kitchen.

Get a free quotePressing Kitchen Sink

Pressed sinks are formed by molding sheet metal, offering a wide range of shapes and precise dimensions. This process results in a smooth surface, making cleaning effortless.

Get a free quote1.jpg)

Kitchen Faucet

Kitchen faucets are essential for daily kitchen tasks. They come in various styles, finishes, and functionalities to suit different kitchen designs and preferences,you can select the perfect kitchen faucet to enhance the functionality and style of your kitchen.

Get a free quoteDexing Hot Sale Products

Why Choose Dexing

We’re committed to delivering exceptional products. Our advanced manufacturing processes and strict quality standards ensure that every product meets the highest standards. With a wealth of OEM experience, we can customize solutions to meet your specific needs.

Get A free quoteHandmade Kitchen Sink Manufacturing Process

The production process of handmade stainless – steel kitchen sinks involves several key steps. Each step is crucial to ensure the quality and functionality of the final product.

Material Preparation

- Stainless steel sheets are selected as the primary material. These sheets should meet certain quality standards, usually with specific thickness and grade. High – quality stainless steel, such as 304 or 316 grade, is commonly used for its durability and resistance to corrosion.

Cutting

- The first step in the actual production is cutting the stainless steel sheets to the desired size and shape of the sink. Advanced cutting machines, like laser cutters or waterjet cutters, are often employed.

- After cutting, the edges of the sink pieces may need to be trimmed or deburred to ensure they are smooth and free from any sharp protrusions.

Bending

- After cutting, they are bent to form the shape of the sink. Specialized bending machines are used to create the sides and corners of the sink. The bending process requires precise control of the angle and curvature to ensure that the sink has the correct dimensions and that the edges fit together properly.

Welding

- Welding is a critical part of the production process. Skilled welders use welding techniques suitable for stainless steel, such as TIG (Tungsten Inert Gas) welding. TIG welding produces high – quality, strong welds with minimal distortion and a clean appearance.

Surface Treatment

- After welding, the welded areas may be polished to blend in with the rest of the sink surface and to remove any discoloration or rough spots caused by the welding heat.

Quality Inspection

- Before the sinks are packaged and shipped, a comprehensive quality inspection is carried out. This includes checking the dimensions of the sink to ensure they meet the specified tolerances. The surface finish is examined for any scratches, dents, or other imperfections.

Packaging

- Packaging materials are chosen to prevent scratches, dents, and other damage that could occur during shipping. The packaging usually includes protective foam or cardboard inserts, and the sinks are securely wrapped to ensure they arrive at the customer’s location in perfect condition.

Client Testimonials

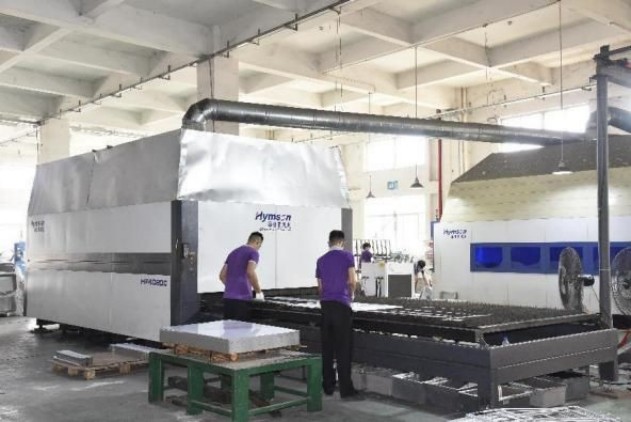

Our Handmade Sink Factory

After Sales Support

Unmatched Customer Support

We’re committed to providing exceptional customer support. From technical troubleshooting to product advice, our dedicated team is here to assist you. Our support services include:

- Real-time Online Support: Get quick answers to your questions via email, chat, or social media.

- Automated Solutions: Access instant support through our self-service tools and FAQs.

- Personalized Assistance: Our experts can provide tailored solutions to your specific needs.

FAQs

MOQ starts at 33 units, ideal for wholesale partners. Custom designs for apron-front or vessel sinks require a 50-unit minimum.

Yes! All stainless steel sinks meet ASTM standards, featuring corrosion-resistant 304 steel and easy-cleaning brushed finishes.

Absolutely. Customize strainers, grids, or racks to complement your kitchen faucets and elevate functionality.

Standard orders ship in 15 days. Custom designs (e.g., farmhouse sinks or transitional profiles) take 25-30 days.

Yes! Our top-mount and undermount sinks include installation kits. We also provide CAD files for precise countertop cuts.